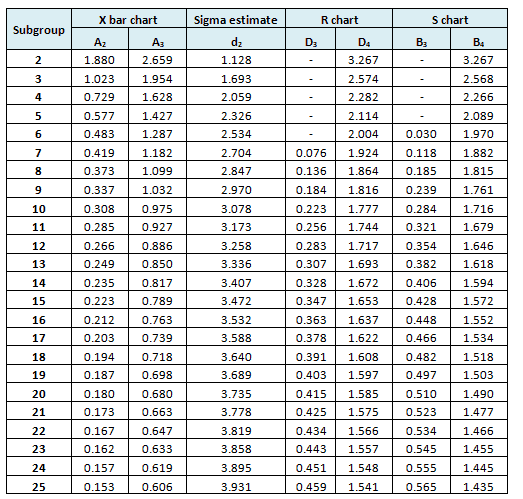

X-bars and R charts can be used to determine process capacity. When we observe X-bars and R(Range) charts we often notice "outliers data points" - which appear outside the control limits - to understand that the process is out of control, and the process needs improvement. By comparing process averages and ranges of different processes or operators, it can be identified which processes or operators are performing well and which processes need to be improved. X-bars and R charts can be used to compare the performance of different processes or operators. So that necessary controls and inefficient processes or items can be removed, which eventually turns into an efficient process.Ĭomparing the performance of different processes or operators This improvement is only possible when complete monitoring of the process is available. It is obvious that positive process change and continuous improvement are necessary to prevent waste and reduce costs. Most units are concerned about waste in their processes. As can be seen by the X-bar, the mean of the process is changing, while the R chart shows that the range of the process is increasing so that the business can understand what are the sources of variation in the process, so that it is easy to take steps for improvement. Naturally, this is an excellent tool for identifying and addressing problems in the process. It can also be used to identify and control sources of variation. So if both are used together it can provide a comprehensive view of the process. For example, X-bar charts are used to track the average value of a process, while R charts are used to track the range of a process. To monitor process stability and consistencyīoth the X-bar chart and the R chart are actually different, but both are used interchangeably. Hence some of the major uses of X-bar and R charts are outlined below in more detail: X-bar and R charts are very popular for providing accurate information on the unit of process shown in the chart. In any industry, it may manufacturing, healthcare or service organizations, the stability and consistency in their processes must be monitored from time to time. Mostly in automotive industry used widely to determine its It may have a drive a subgroup size of two or more to measure standard chart for variables data.

An XBar and R (range) Chart study is a statistical quality control chart used to monitor variables of product criteria.

0 kommentar(er)

0 kommentar(er)